Let's explore the application areas of CNC milling in more detail. It permeates almost every corner of modern manufacturing. Here are some key areas and their specific applications:

1. Aerospace Industry

This is one of the industries with the highest requirements for materials, precision, and reliability.

Specific Applications:

Structural Components: Large and complex aluminum or titanium alloy structural components such as aircraft wing spars, ribs, frames, and doors. These components typically need to be "carved" from a single piece of metal to achieve an extremely high strength-to-weight ratio (i.e., "weight-saving manufacturing").

Engine Components: Turbine blades, bladed disks, engine casings, combustion chamber components, etc. These parts typically use difficult-to-machine materials such as high-temperature alloys and titanium alloys, requiring extremely high precision and surface finish.

Avionics and Control Systems: Precision parts such as radomes, brackets, and navigation equipment housings.

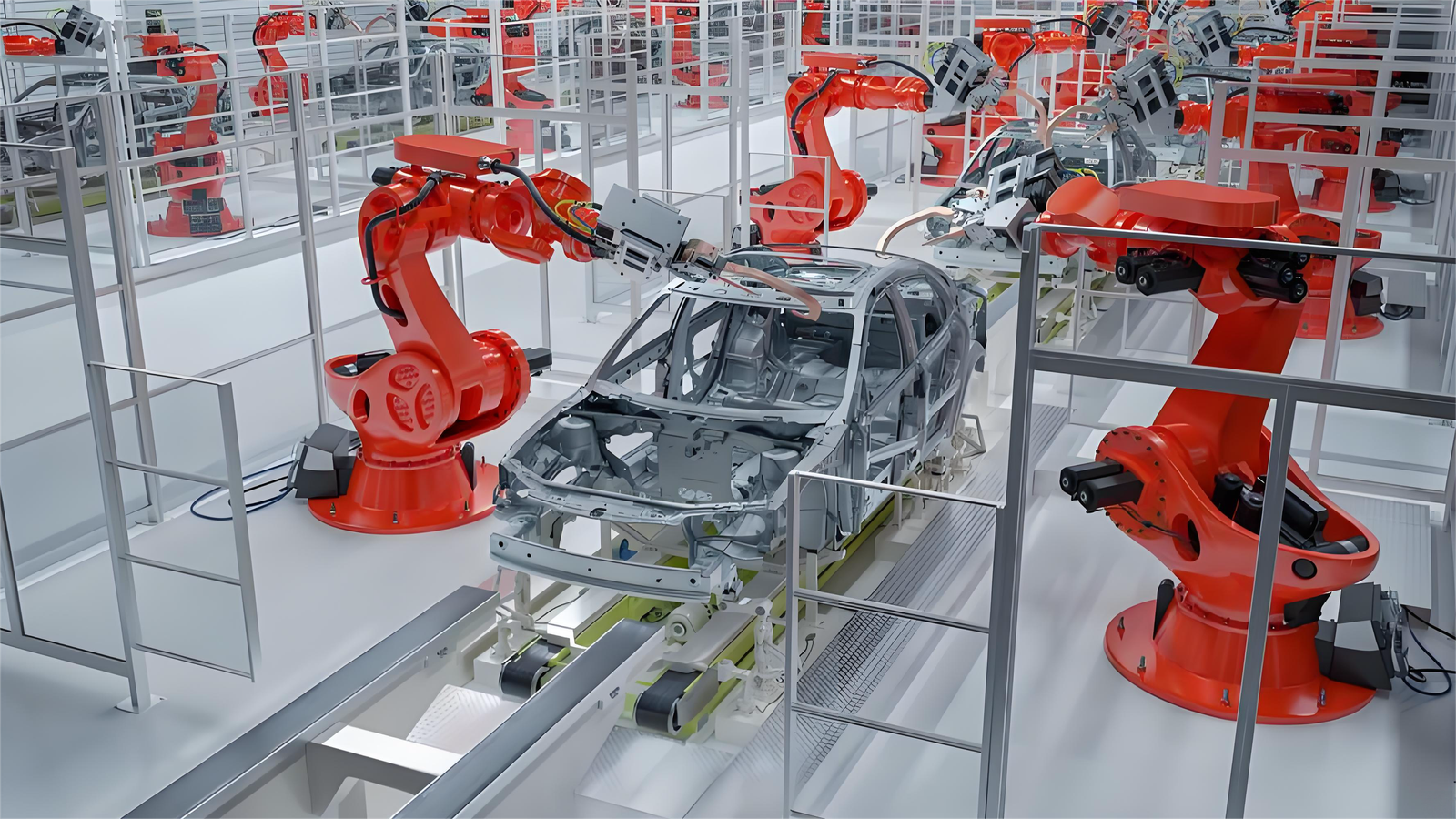

2. Automotive Industry

From prototype development to mass production, CNC milling is ubiquitous.

Specific Applications:

Powertrain:Machining of engine blocks, cylinder heads, crankshafts, gearbox housings, and clutch plates.

Chassis and Suspension:Safety-critical components such as wheel hubs, steering knuckles, control arms, and brake calipers.

Prototypes and Molds:Design prototypes for new vehicles, as well as injection molds and die-casting molds for producing plastic parts such as bumpers, dashboards, and door panels.

High-Performance Modification and Racing:Small-batch, lightweight parts customized for racing cars or high-performance modifications.

3. Medical Devices

Requires extremely high biocompatibility, precision, and surface quality.

Specific Applications:

Implants:Artificial joints (knee, hip), bone plates, dental implants, cranial repair plates, etc. These typically use titanium alloys, cobalt-chromium alloys, or medical-grade PEEK materials.

Surgical Instruments:Endoscopic components, surgical robot arms, bone drills, scalpel handles, etc.

Diagnostic Equipment:Precision parts in MRI and CT scanners, reagent kit molds, and analytical instrument housings.

4. Electronics and Communications

Pursuit of miniaturization, high integration, and efficient heat dissipation.

Specific Applications:

Casings and Structural Components: Metal frames for smartphones, unibody laptops, server chassis, etc.

Heat Heatsinks: High-precision heatsinks on CPUs/GPUs, maximizing heat dissipation area through milling dense fins.

Connectors and Waveguides: Precision components in communication equipment such as RF connectors, microwave circuit boards, and waveguides.

Tooling and Fixtures: Fixtures used for precise component positioning on PCB assembly lines.

5. Mold Manufacturing

CNC milling is the dominant technology in mold manufacturing.

Specific Applications:

Injection Molds: Used to produce almost all plastic products, from water bottles to car taillights.

Die Casting Molds: Used to produce parts made of metal alloys such as zinc, aluminum, and magnesium, such as gears and housings.

Stamping Molds: Used for sheet metal forming, such as car doors and computer cases.

Blow Molds: Used to produce hollow plastic products, such as bottles and fuel tanks.

6. Energy Industry

Specific Applications:

Traditional Energy: Steam turbine blades, complex generator components, valve bodies, oil drilling equipment parts.

Renewable Energy: Wind turbine gearbox components, solar panel mounting brackets and connectors, hydroelectric turbine blades.

7. Defense and Military Industry

Specific Applications:

Weapon system components, armored vehicle parts, missile guidance system structural components, night vision device housings, communication equipment, etc. Strict requirements are placed on the robustness, reliability, and performance under extreme environments of materials.

8. Industrial Equipment and Machinery

Specific Applications:

Automation Equipment: Robot end effectors, conveyor belt components, precision linear modules.

Machinery Equipment: Manufacturing parts for other machine tools, such as spindle boxes, slides, etc.

Pumps and Valves: Complex impellers, pump casings, valve cores, requiring excellent sealing and hydrodynamic characteristics.

9. Consumer Goods and Cultural & Creative Industries

Specific Applications:

High-end Consumer Goods: Watch cases and bracelets, jewelry molds and prototypes, camera bodies, musical instrument components (such as saxophone bodies).

Customized Products: Custom bicycle frames, drone frames, high-end audio components.

Art and Architecture: Metal sculptures, architectural models, decorative components.

---In summary, the application areas of CNC milling can be categorized as:

Any field requiring high precision, complex shapes, and excellent surface quality for prototypes or parts.

Any field using hard materials (metals, engineering plastics, composite materials).

Any field involving mold manufacturing.

Its core value lies in seamlessly and accurately transforming digital designs into reliable physical entities, making it an indispensable cornerstone technology in modern high-end manufacturing.