Simply put, the core difference between three-axis, four-axis, and five-axis CNC machine tools lies in their degrees of freedom of motion and machining capabilities:

* Three-axis (X/Y/Z linear axes) are suitable for simple planar machining, with low cost;

* Four-axis (adding a rotary axis) can handle cylindrical surfaces and multi-faceted parts, reducing clamping;

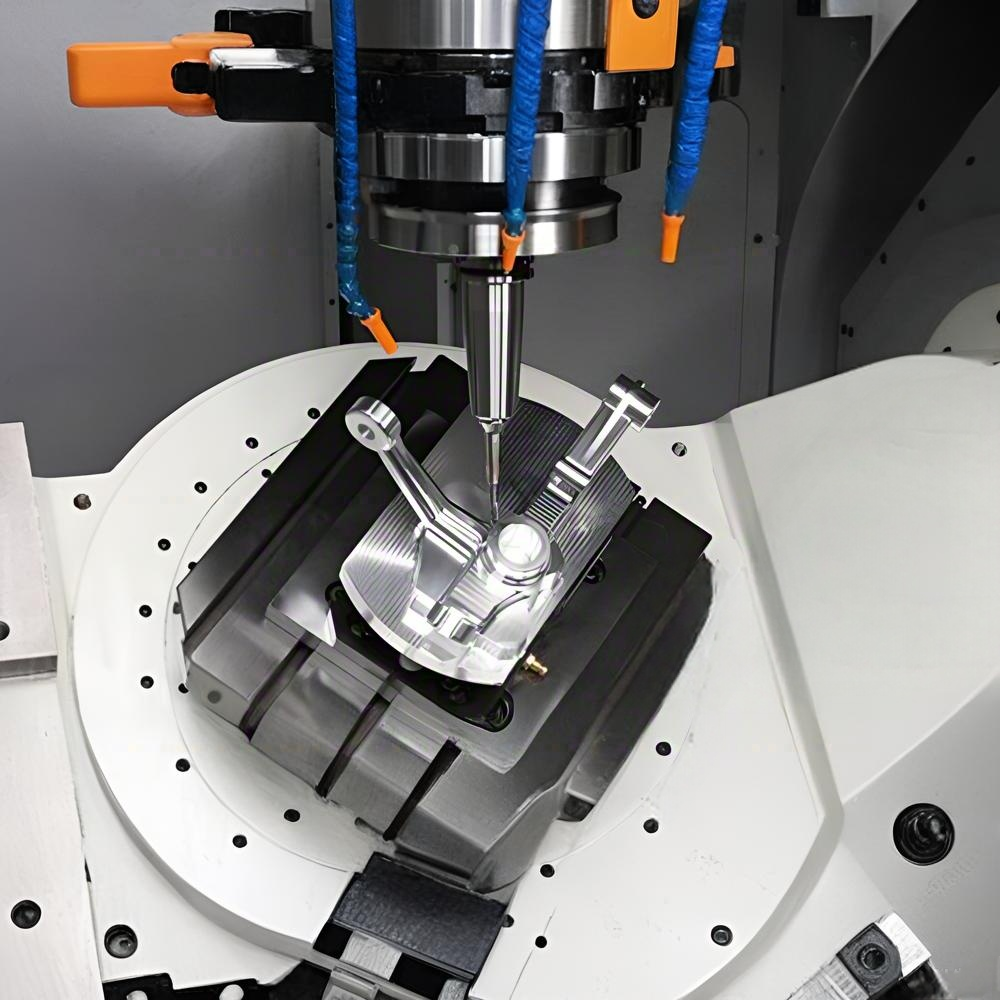

* Five-axis (adding two rotary axes) can complete complex curved surfaces in a single clamping operation, offering the highest precision but at a high cost, suitable for high-end fields such as aerospace.

Selection Recommendations:

For simple parts, choose three-axis: Prioritize for cost-sensitive, high-volume production.

For multi-faceted or rotating bodies, choose four-axis: Reduces clamping times and improves consistency.

For complex curved surfaces, choose five-axis: Essential for high-precision applications, but return on investment needs to be evaluated.