1. Reduced Machining Time and Improved Machining Accuracy

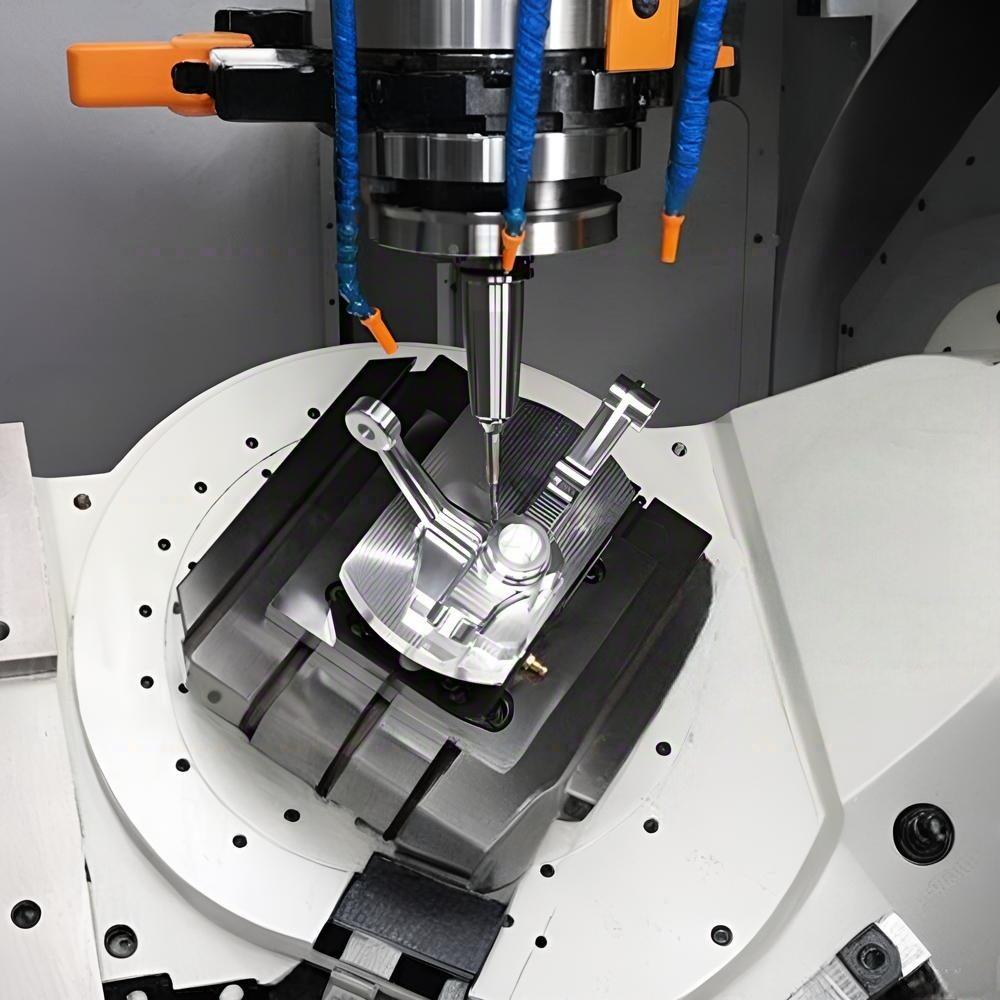

The biggest feature of a 5-axis machining center is that it can machine all five surfaces in a single setup. This is also known as machining angle avoidance. With a linkage machine tool, the C-axis can rotate without restriction, and the A-axis can rotate approximately 130 degrees. These characteristics ensure that there is no interference during machining.

This results in machining being completed in a single setup, avoiding the repeated positioning errors caused by multiple setups. Simultaneously, a single setup saves a significant amount of time, improving work efficiency. It reduces the time from product to shipment and decreases inventory.

2. Reduced Equipment Investment Costs, Workshop Footprint, and Number of Workshops

5-axis machining centers are multi-functional machining centers, often including turning capabilities, and can even encompass lathes, milling machines, and vertical grinders. As we all know, vertical grinders are currently very expensive. Cost and cycle time calculations show that 5-axis machining offers higher cost-effectiveness. Previously, production processing was mainly done in a segmented, engineering-based manner. The problem with this production method is that a significant amount of waiting time cannot be eliminated. However, the intensive production represented by five-axis composite machining equipment only requires initial waiting and debugging time. Furthermore, with the widespread availability of various machine simulation software in China, programming can be completed simply by importing raw data, significantly shortening the initial preparation period. Therefore, the automotive parts and high-end manufacturing industries abroad are primarily based on five-axis systems.