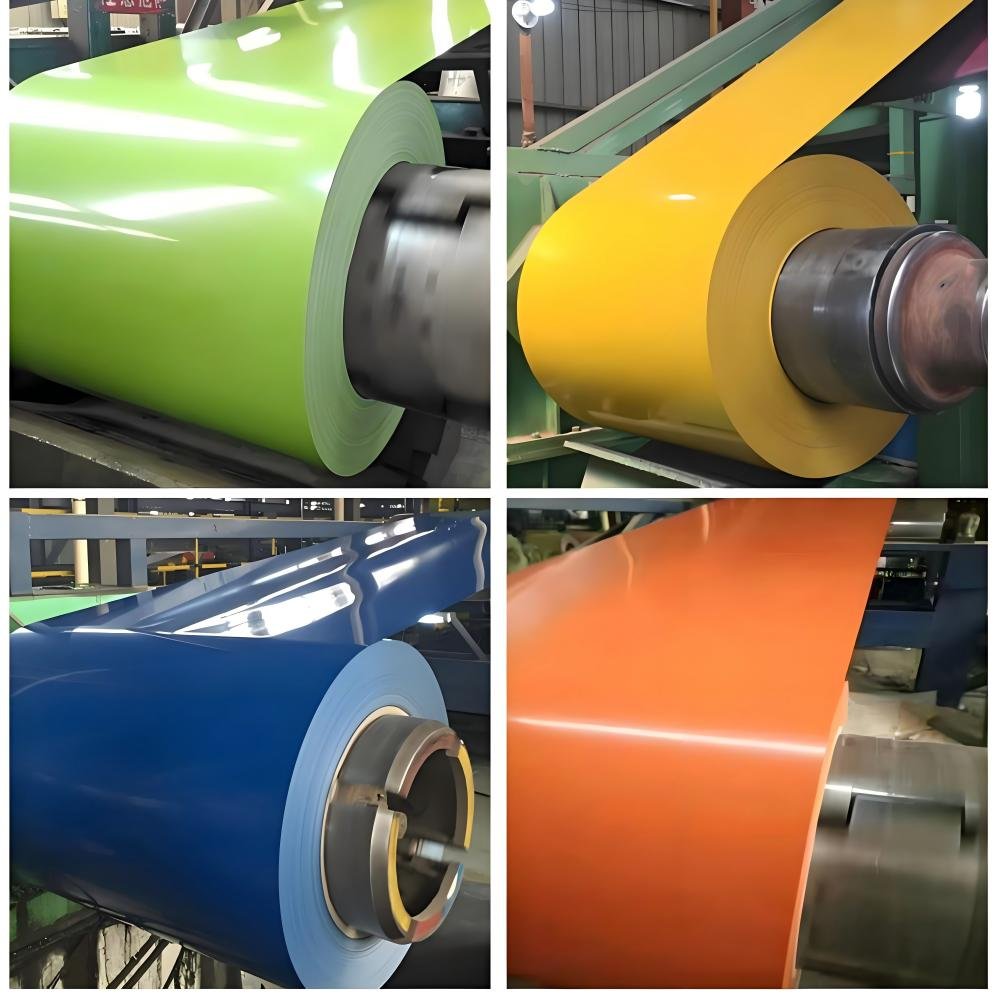

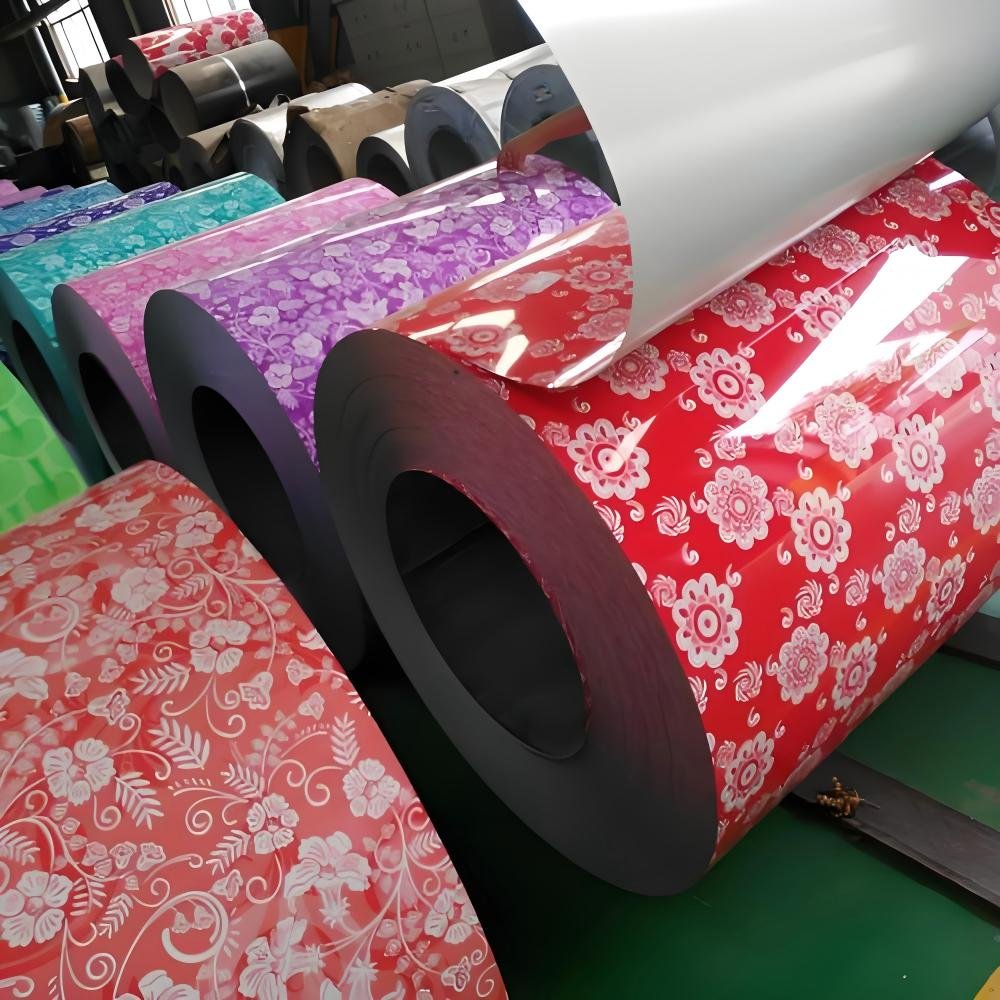

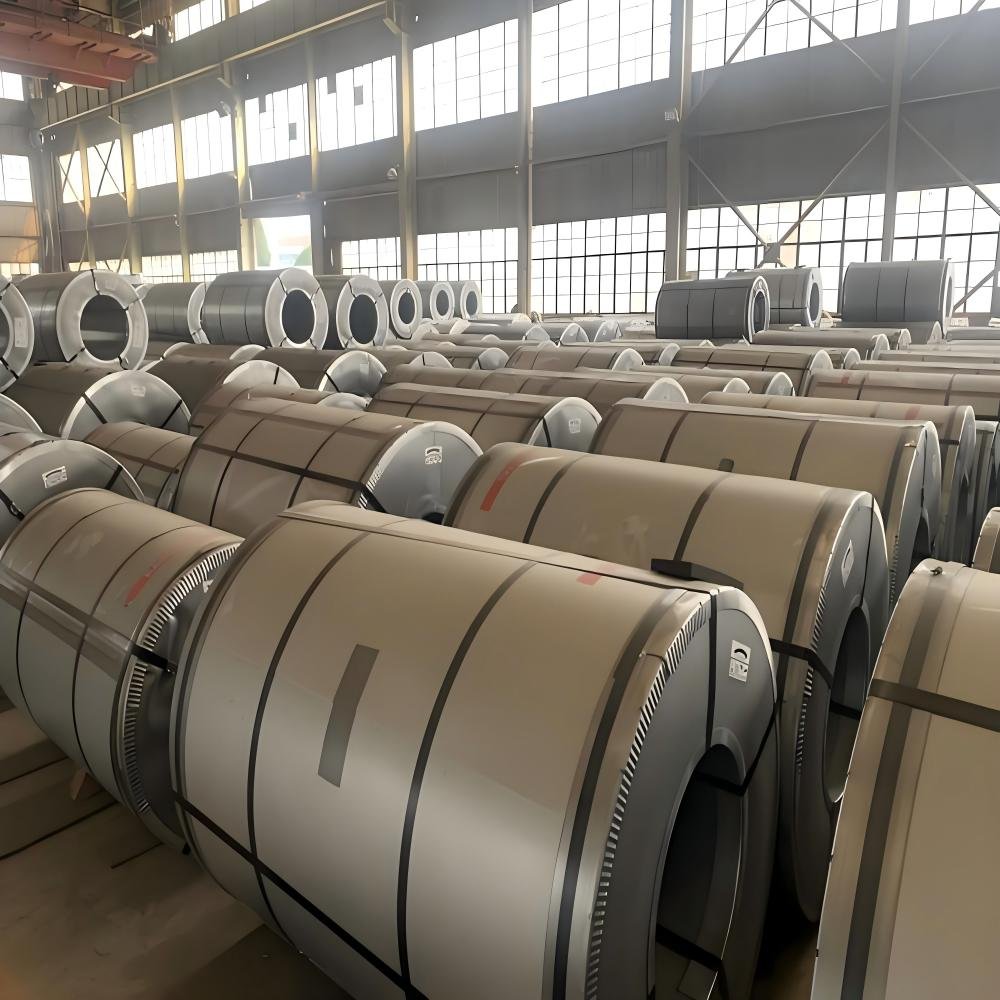

Color-coated steel refers to pre-painted steel sheet, which is coated with an organic coating. It offers excellent corrosion resistance, vibrant colors, an attractive appearance, and easy processing and shaping, retaining the inherent strength of the steel sheet at a lower cost.

Color-coated steel sheet is widely used in industries such as construction, home appliances, and transportation. In the construction industry, it is primarily used for roofs, walls, and doors in industrial and commercial buildings such as steel-structured factories, airports, warehouses, and cold storage facilities. Residential use of color-coated steel sheet is less common.

Advantages:

Seismic Resistance

Low-rise villa roofs are mostly pitched, so the roof structure typically utilizes a triangular truss system made of cold-formed color-coated steel members. After the structural panels and gypsum board are enclosed, the lightweight steel members form a highly sturdy "plate-rib structure" system. This structural system offers enhanced earthquake resistance and resistance to horizontal loads, making it suitable for areas with a seismic intensity of 8 or higher.

Wind Resistance

Color-coated steel structures are lightweight, strong, have excellent overall rigidity, and are highly deformable. The building's deadweight is only one-fifth that of a brick-concrete structure, and it can withstand hurricane-force winds of 70 meters per second, effectively protecting life and property.

Durability

Color-coated steel residential structures are constructed entirely of cold-formed, thin-walled steel components. The steel frame is constructed of ultra-corrosion-resistant, high-strength, cold-rolled galvanized steel sheet. This effectively prevents corrosion during construction and use, extending the service life of the lightweight steel components. The structure can last up to 100 years.

Thermal Insulation

The color-coated steel sandwich panels primarily utilize fiberglass insulation, which provides excellent thermal insulation. Used as exterior wall insulation, they effectively prevent "cold bridges" in the wall and achieve superior thermal insulation. R15 insulation wool, approximately 100mm thick, has a thermal resistance equivalent to a 1m-thick brick wall. Soundproofing

Soundproofing is a key metric in evaluating residential properties. Windows installed in the color-coated steel + light-weight steel system utilize insulated glass, offering excellent soundproofing, exceeding 40 decibels. Walls constructed with light-weight steel keels and insulating gypsum board can achieve soundproofing of up to 60 decibels.

Healthiness

Dry-construction reduces environmental pollution caused by waste. The color-coated steel is 100% recyclable, and other supporting materials are also largely recyclable, aligning with current environmental awareness. All materials are green building materials, meeting ecological requirements and promoting health.

Comfort

The color-coated steel walls utilize a highly efficient, energy-saving system with a breathing function, regulating indoor air humidity. The roof features ventilation, creating a flowing air space above the roof to ensure adequate ventilation and heat dissipation within the roof.

Quickness

The entirely dry-construction process is unaffected by the environment or season. A building of approximately 300 square meters can be completed from foundation to finish by just five workers in 30 working days.

Environmental

The color-coated steel is 100% recyclable, making it truly green and pollution-free. Energy Efficiency

High-efficiency energy-saving walls are used throughout the building, providing excellent thermal insulation, sound insulation, and achieving a 50% energy saving standard.

Contact Us

- +86-13920256138

- +86-13920256138

- +86-13920256138

- krisfyt65@gmail.com

- +86-13920256138